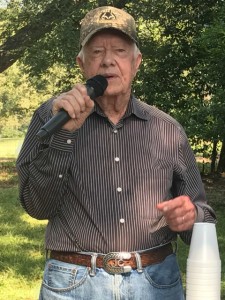

Albert Culbreath, a 28 plus year professor of Plant Pathology at the University of Georgia Tifton campus, works primarily with foliar fungal diseases of peanut and tomato spotted wilt virus of peanut. Culbreath arrived at UGA shortly after tomato spotted wilt showed up, so needless to say they have a long history. “We’ve made tremendous progress dealing with that disease but it’s still around and still causes problems. Leaf spot has been a problem with peanuts as long as we’ve been growing peanuts in Georgia. We’re working on resistance and integrated management for both of those diseases, but with the leaf spot we’re still very heavily dependent upon fungicides for control of those,” says Culbreath. An awful lot of his work is geared toward looking with the different breeding programs, trying to help develop and utilize better resistance to spotted wilt and the leaf spot diseases.

The spotted wilt part of peanut RX is a tremendous decision tool for growers so the biggest factor with that is the ranking of variety for resistance to tomato spotted wilt. “We spend a lot of time trying to rank the cultivars depending on how susceptible or resistant they are. That’s the primary thing after planning date choice and typically with tomato spotted wilt, the earlier you plant, the greater the risk of damage from spotted wilt so if you’re planting a more moderately resistant variety or more susceptible variety, you would want to dodge an early planting,” the UGA researcher continued. The peanut RX would help with decisions like that. We only have one insecticide that provides suppression of spotted wilt. Thimet. There’s currently a few insecticides that work well on thrips or control the vector of spotted wilt, but Thimet is the only one that helps suppress the disease itself so those all come into play. Those are incorporated into the index and the index also helps you look at the additive effects of the different factors We will use the RX for the other diseases too and things like planting dates are just the opposite for tomato spotted wilt and leaf spot. “The earlier you plant, the higher the risk for tomato spotted wilt but the lower the risk for leaf spot”, says Culbreath. “If you have a low risk variety for tomato spotted wilt, we’re using that to let growers know that you can plant and dodge some of the leaf spot pressure. We have severe problems with fungicide resistance to some of the fungicide classes,” he adds. Some fungicides don’t work alone in Culbreath’s fields now so he’s looking at different combinations, different alternations that will prolong the utility of those fungicides so that’s the main focus of what he has going on in Plains at the University of Georgia’s Southwest Georgia Research & Education Center.

Also at this tour stop, attendees were able to enjoy grilled pb&j’s presented by the

Also at this tour stop, attendees were able to enjoy grilled pb&j’s presented by the

![IMG_9750[1]](http://georgiapeanuttour.com/wp-content/uploads/2017/09/IMG_97501-300x225.jpg)