After a delicious lunch at Moby Dick Restaurant in Colquitt, Georgia, tour attendees traveled right down the road to Birdsong Peanuts’ shelling facility. Birdsong Peanuts is a family-owned company based out of Suffolk, Virginia, and has been in business for more than 100 years, extending five generations. During this time, the company has delivered nutritious peanuts to manufacturers around the world to make food products such as peanut butter, trail mix, snack nuts, candy and many other items. Other than the school system, Birdsong Peanuts is the largest employer in Miller County, Georgia.

After a delicious lunch at Moby Dick Restaurant in Colquitt, Georgia, tour attendees traveled right down the road to Birdsong Peanuts’ shelling facility. Birdsong Peanuts is a family-owned company based out of Suffolk, Virginia, and has been in business for more than 100 years, extending five generations. During this time, the company has delivered nutritious peanuts to manufacturers around the world to make food products such as peanut butter, trail mix, snack nuts, candy and many other items. Other than the school system, Birdsong Peanuts is the largest employer in Miller County, Georgia.

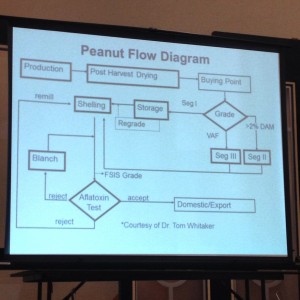

In Birdsong’s business, peanuts are carefully selected directly from farmers’ fields. After selection, they are cleaned, shelled, sized and shipped in truckloads or rail cars in lots to manufacturers who turn them into many popular food items.

During the peanut tour visit, attendees had a chance to walk through the shelling plant and see how peanuts are brought in, shelled and prepared for shipping to manufacturers. Joey George, Colquitt shelling plant manager, gave participants an overview of what to expect before entering the plant and went through the steps of the process:

- Cleaning: peanut vines, glass, metal, sticks, etc. are removed from the peanuts; de-stoners are also used to remove rocks and stones from the product

- Shellers: several banks of shellers are located in the plant; the size of the peanut determines which bank shells it; about 80 percent of peanuts are shelled on what is considered the “first pass”

- Gravity: used to separate any foreign material left after the peanuts have been shelled

- Sorters: “electronic eyes” used to pick out dark spots and blemishes unwanted in product

- Sizers: includes jumbo, medium and number one sizes; splits are also included; Carter Day machines are then used for additional sizing

- Packaging: 2,200 lb bags are packaged out; 20 or 21 bags are used to make a complete lot; it takes about 60 seconds to fill a bag; this plant fills about 600 bags per day

George went on to discuss the general operations of the plant.

“At our facility we run 24/7 year-round; we have a few holidays we take, but we shell year-round,” he said. Due to the large volume of peanuts shelled, the facility isn’t able to close. “We shell about 1.5 million pounds of peanuts a day, so that’s a lot of peanuts that have to go somewhere.” George also mentioned the facility ships out by rail and truck. Some peanuts are also stored in cold storage. According to George’s knowledge, this facility houses the largest peanut storage warehouse in the United States.

One thing that makes Birdsong unique is their commitment to focus solely on peanuts. From planting, harvesting, shelling and shipping, Birdsong monitors every peanut to make sure it is the highest quality product sent to manufacturers. Today, the company operates six shelling plants throughout the peanut belt made up of 11 states extending from Virginia to New Mexico. In addition, Birdsong operates 85 buying points where farmers’ stock peanuts are bought and stored. Also, cold storage warehouses, which enable Birdsong to keep peanuts in a protected environment until shipped to customers, are located at some facilities. Finally, Birdsong has extensive farm operations in Florida and Texas where they grow peanuts on 100 percent irrigated land.

For a glimpse inside one of Birdsong’s shelling facilities, view the video below.